As the Statue of Liberty reopens to the public Urban Omnibus interviews Lehrer McGovern about the 1984-6 renovation of the statue in preparation for its centennial celebration.

Tomorrow, on Independence Day, one of our country’s most beloved monuments will re-open to the public for the first time since Superstorm Sandy destroyed the docks, promenade, and much of the infrastructure on Liberty Island last October. While the extreme winds and flooding wreaked havoc on mechanical, electrical, plumbing, and sewage systems, the Statue of Liberty itself was not damaged. The fact that the statue withstood the storm is a testament not only to the its original design — the elasticity of the structural support system Gustave Eiffel designed makes it highly weather-resistant, literally swaying in the wind — but also to the various attempts over the years to maintain and upgrade the historic structure. Indeed, Eiffel devised ingenious engineering solutions to realize the vision of political thinker Edouard de Laboulaye, sculptor Auguste Bartholdi, and architect Eugene Viollet-le-Duc, the original designer of the internal structure who died unexpectedly in 1879 before the plans were complete. Eiffel’s solution to the structural challenges inherent to Bartholdi’s design prefigured the curtain-wall construction of the 20th century skyscraper: the statue’s skin is not load-bearing but is instead supported by a skeletal substructure of a 92-foot central pylon girded with lightweight and malleable trusswork that assumes the irregular shape of Lady Liberty’s body. Nonetheless, defects from the original construction have beleaguered the statue’s custodians since its opening in 1886. The head and arm were both misaligned with her body by more than a foot, forcing their attachment to different parts of the supporting structure than originally intended. And the chemical reaction between the copper of the skin and the iron of the armature was always bound to cause major problems. As Edward Cohen put it to The New York Times in 1985, “If you put iron and copper together with a little moisture, you get a battery.” A century of quick fixes to these and other challenges – including the use of asbestos, leather, tar, and lots of green paint – only exacerbated the issues that long plagued the monument.

Cohen, an engineer who spent 50 years with the firm Ammann and Whitney, was part of a team, including architecture firms Swanke Hayden Connell and Thierry Despont, that worked tirelessly for two years to completely renovate the statue in advance of its centennial in 1986, a celebration presided over by Presidents Ronald Reagan and Francois Mitterand. Another principal collaborator on this group effort was the construction management firm of Lehrer McGovern, which was a modest four-year old start-up in 1983 when it beat out many larger and more experienced companies to win the sought-after renovation contract for the Statue of Liberty. The difficulty and high profile of this project accelerated the firm’s ascent to become one of the most respected construction management companies in the country. Thirty years later, on the eve of the Statue’s re-opening after eight months of repairs, Rosalie Genevro, Executive Director of the Architectural League, sat down with Peter Lehrer, one of the founders of Lehrer McGovern, to ask him to describe this pivotal project in his career. The story he tells touches on only some of the many fascinating details of this complex feat of historic preservation – from coordinating on-site logistics, to identifying suitable building materials and processes, to sourcing French artisans skilled in traditional metalworking techniques. As Lehrer’s description makes clear, the Statue of Liberty’s status as an enduring icon of freedom and the promise of America continues to overshadow the marvel of its engineering, construction, and ongoing efforts to maintain it.

— C.S.

I’ve had a life-long fascination with the construction business. My father immigrated to this country as a carpenter, and I remember following him around as I was growing up in Hell’s Kitchen. The thought never entered my mind that I would do anything other than build buildings. So I went to a university to become a civil engineer, and I have been in the construction business ever since.

When I graduated, I started working for a major builder. One of my first jobs was as an assistant superintendent at the Pan Am (now MetLife) building. Sixteen years later, I was president of the eastern region, the largest portion of the company. In 1979, Gene McGovern and I formed Lehrer McGovern. It started around our kitchen table in Scarsdale, with my wife answering the phone. But within a few years, it had become a major construction company in New York. Lehrer McGovern was one of the early firms doing construction management – that was 100% of our business – which essentially means that the entire focus of the company was serving the clients’ best interests. I think the firm was respected because of its tenacity, its innovation, the caliber of its employees, and its ability to complete projects on time.

In 1983, we got the job of a lifetime, restoring the Statue of Liberty. Our client was the Statue of Liberty-Ellis Island Foundation, and we had a very fixed completion date. There was no room for even one day’s delay because on July 4th, 1986, President Ronald Reagan was going to turn the lights on in the torch. 1986 was the 100th anniversary of the Statue’s initial construction. The project needed to be finished flawlessly and on time.

When France donated the 100-foot statue in 1886, it was agreed that the Americans would build the pedestal. The U.S. was unsuccessful in raising the money in time, so when the 214 crates arrived on Liberty Island, the pedestal was not yet ready. It was only through the efforts of Joseph Pulitzer, who used his newspaper The World to campaign for small donations – in many cases pennies being sent in from schoolchildren – that the money was raised to complete the pedestal.

One hundred years later, when the Parks Service, which is responsible for the statue, recognized that there were many problems that needed to be fixed, President Reagan once again appealed to private citizens for donations, appointing Lee Iacocca to create a foundation to fundraise and manage the process of reconstruction. Although much of the monies was raised by corporations, once again one million dollars was raised from pennies donated by school children.

I think part of the fascination with the reconstruction was that literally everything that we had to do had never been done before. We were looking at groundbreaking, seemingly impossible problems, and coming up with some very unconventional solutions. We worked closely with the design team and with the National Parks Service, but it was Lehrer McGovern’s responsibility to find the solutions, to present and test them.

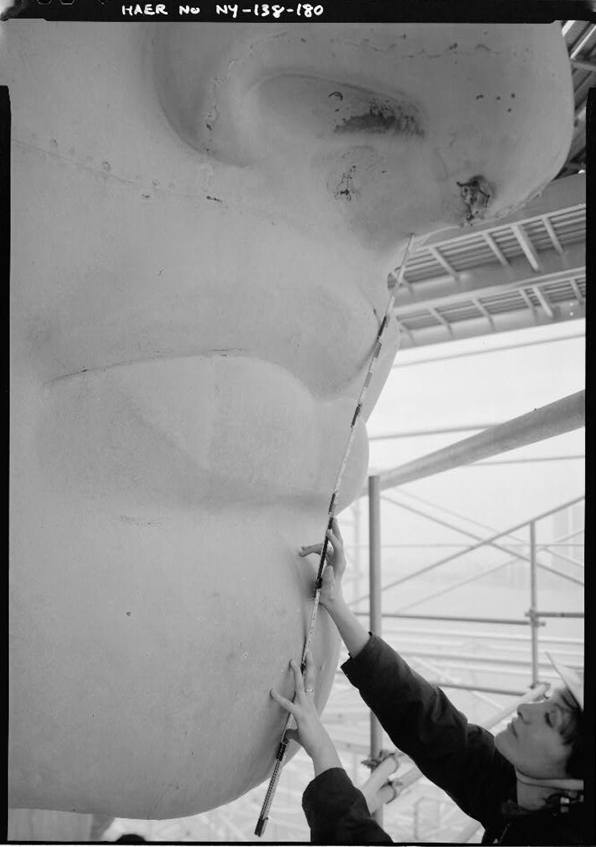

Originally, the statue was already designed and well into construction before Gustave Eiffel was engaged to design the internal structure, which consisted of vertical steel members and a series of intermediate members. But what holds the copper skin to the Statue are approximately 600 armature bars made of a ferrous metal that follow the contours of the skin. To prevent the electrolytic reaction between the copper and the ferrous metal, they used an asbestos separator. But over time, the asbestos separator deteriorated and water started to penetrate through what we called the saddles, which clamped over the armature wall, riveted to the skin of the statue. What we found was that the expansion and corrosion of these armature bars had caused the fastening for many of these saddles to become disengaged.

The government’s response to this water infiltration was to coat the entire inside of the statue with a tar material. But that actually accelerated the deterioration because the water then became trapped between the tar and the skin. And then it looked so bad that they continuously painted the inside of the statue with green paint. By the time we started working on it, the statue would have failed and potentially collapsed if the corrective work was not done.

The job required working in a very confined environment, and conventional materials would be toxic and dangerous to either the workers or to the statue. We ended up removing the paint with liquid nitrogen, which was donated by Union Carbide. We literally froze the paint off!

As workers and material had to come by boat every day, we had to build our own pier. And we had barges docked with those gigantic tanks of liquid nitrogen that we would spray on the statue to make the paint fall right off.

The next challenge was figuring out how to get the tar off. We tried all sorts of different solvents, and amazingly we found that a solution of sodium bicarbonate, or baking soda, would remove the tar. Arm & Hammer donated the sodium bicarbonate. In a sense, this was probably the world’s largest Alka-Seltzer, and we were able to remove all of the tar. Afterwards, we were left with what the inside of the statue looked like when it was originally erected, which enabled us to go in and repair all of the armature bars. At the same time, because there was so much deterioration in the torch and the flame, we were faced with a very elaborate process of disengaging the existing torch and flame and lowering them to the ground. At the same time we rebuilt the flame in keeping with its original design: solid sheets of copper. It’s now lit externally, so there is no possibility of water infiltration. Now, when you look at it at night, it’s glowing, it has gold leaf paint on it surrounded by very powerful lighting.

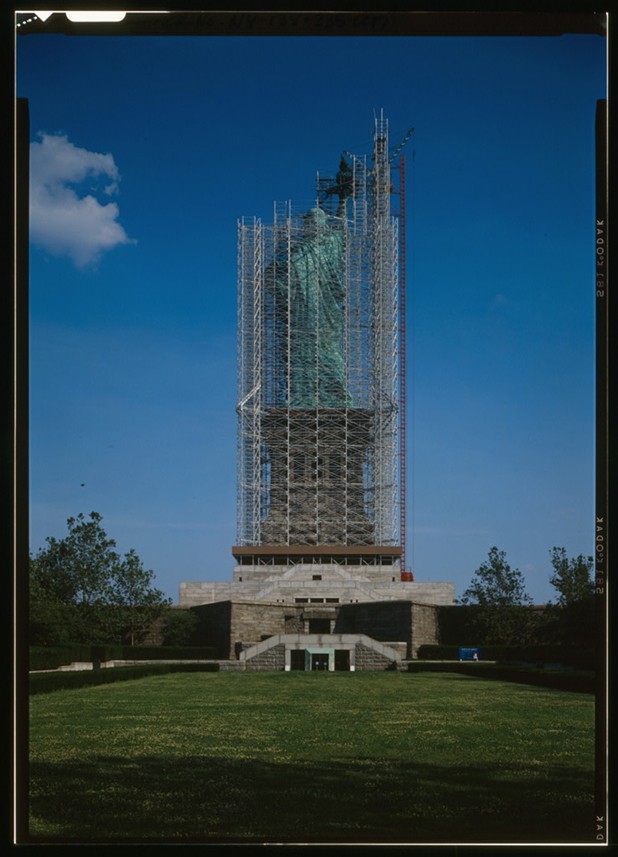

There were countless other aspects to this complex project: creating an emergency elevator within the pedestal, improving the ventilation system, repairing the circular stair. Providing access for the work to be completed required the scaffolding itself to be a creative and functional work of art. The scaffolding was constructed by a firm called Universal Builder Supply (UBS), and it still holds the world record for the highest freestanding scaffold ever erected.

One of the very first challenges we had to solve was finding artisans who were able to work in repoussé, the metalworking technique used in the original construction of the statue. The technique involves creating negative molds out of wood and plaster and hammering flat sheets of copper into those molds. It’s a skill that doesn’t really exist here, so we went to Reims, France, and brought back ten French craftsmen – only one of whom was able to speak English – to do all the copper restoration. We set up a shop on the island with their tools and, of course, we had to solve a union problem since they obviously didn’t belong to a construction union.

Since then, I’ve been fortunate to work on a wide variety of projects, from Euro Disney to London’s Canary Wharf, to the 1996 Olympics in Atlanta, to the Central Park Zoo renovation. But rebuilding the Statue of Liberty was an incredible, special experience. It was an honor to work on this monument, and the more you learn about how innovative the design actually was, the more you appreciate this symbol of liberty in our country.

My interest has always been to figure out how to do things that others think can’t be done. Looking forward, I’d love to be someone who helps protect the city against future floods. I’ve done a fair amount of work on flood mitigation, so I’m aware just how awesome the task at hand is. I just hope the needs are realized before it’s too late.