Aaron Seward reports for The Architect’s Newspaper: IN DETAIL> 837 WASHINGTON STREET. Morris Adjmi adds a twisting topper to a meat packing building.

The design of the addition’s exoskeletal structure references Greenwich Village’s Street grid.

The orthogonal street grid of New York City’s Commissioners’ Plan of 1811 collides with Greenwich Village’s wickerwork layout at 14th Street. While everything above that mark is rectangular blocks, below there is a series of odd triangular leftovers in the urban fabric. The difference between these two conditions served as the primary inspiration behind Morris Adjmi Architects’ design of 837 Washington Street, a 54,000-square-foot spec commercial building developed by Taconic Investment Partners at the corner of 13th Street in the Meat Packing District.

The site was home to an existing brick building that was once used for the purpose that gives the neighborhood its name. Two stories tall on Washington Street, it steps down to one story on 13th and is distinguished by a two-tone brick facade and a now-restored steel canopy—one of the hallmarks of a district that is protected by the Landmarks Preservation Commission.

Required to preserve this piece of history, but eager to wring out every bit of allowed floor area, Taconic asked Adjmi to design an extension for the top of the structure. Adjmi—who has built up quite a repertoire of expansion projects of this sort—responded with a modern addition that looks to the area’s high-design newcomers (High Line, Standard Hotel, Whitney Museum, etc.) as much as it does to its industrial heritage.

|

|

|

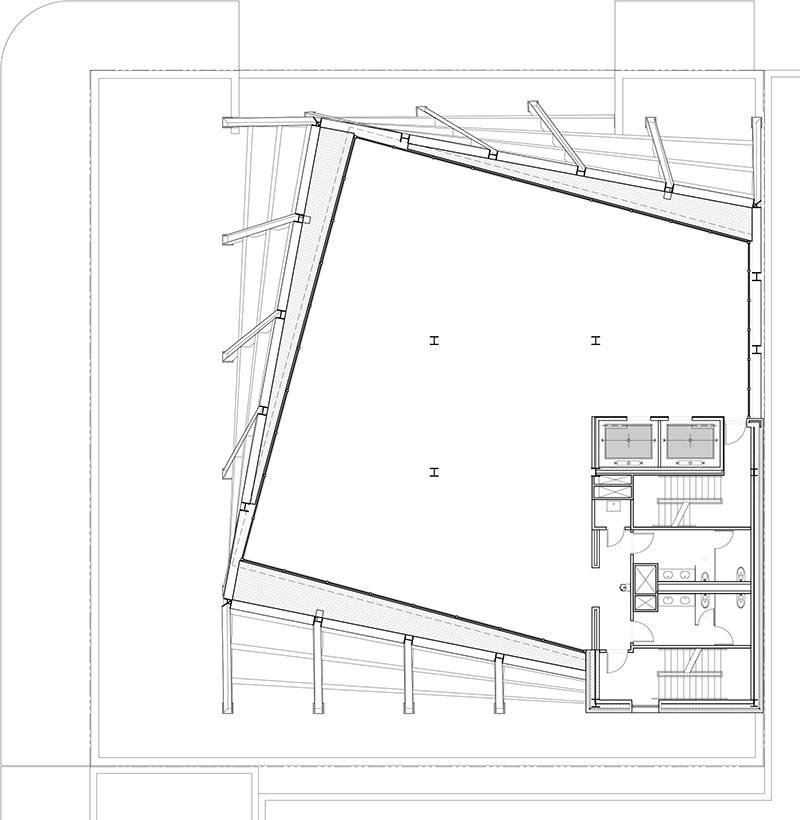

If the existing building represents the right angles of the Commissioners’ Plan, the rooftop extension expresses the village street condition. “The notion,” said Adjmi, “was to create a space where two buildings can coexist, rather than one being an addition to the other.” The expansion rises five levels above the brick building’s first story. Roughly square shaped, each floor is slightly smaller in area to the one below it and is rotated slightly in plan. This leaves triangular spaces outside of each floor’s divided light window wall, much like the triangular plazas found throughout the Village, which will be planted, drawing a connection to the neighboring High Line.

The expansion is supported by a structural steel exoskeleton—another High Line reference—featuring sloped columns that, like the building’s floors, twist in plan as they go up the elevation. While this expression does indeed resemble the way the Village streets veer off from the straight-as-an-arrow avenues coming down from uptown, it also created a structure that wanted to rotate and fall over. The structural engineers at Gilsanz Murray Steficek (GMS) were hard pressed to design an efficient and cost-effective scheme that would stand up against its live and dead loads.

Rotating each floor in plan opened up triangular exterior sections that will be planted.

The solution mixes a conventional system with custom elements. Conventionally, the building is supported by a perimeter moment frame with a braced frame core, which is situated at the interior-most corner of the lot. Custom elements include built-up plate girders for the spandrel beams that were designed to handle the stresses imposed by the torqued shapes while maintaining the look desired by the architect. The columns themselves are spliced at every floor, rather than every other floor, and rotated five degrees to create a twisting profile. Intumescent painted and epoxy coated in black, the sloping columns meet new vertical columns that run through the existing building down to a newly dug basement and onto a freshly poured matt foundation.

Having the majority of the structure on the exterior and in the core allowed the designers to only use three columns on the interior, opening up more useable floor space. This did create thermal bridging issues, however, and so non-conductive shims were used to create thermal breaks between inside and outside. To maximize floor-to-ceiling heights the engineers also staggered the placement of the metal decking, allowing them to keep floor-framing members down to W12s.

Since the structure also serves as the architectural expression, GMS worked with Adjmi to detail the connections between members. “We worked closely with Morris to develop the connection details, doing isometric drawings and going back and forth on bolt issue, where we usually release that to the fabricator,” said Joseph Basel, GMS partner in charge of the project. “It was a great project and really interesting for us.”